High-Precision Mold Manufacturing

– Our Foundation for Quality.

Introduction

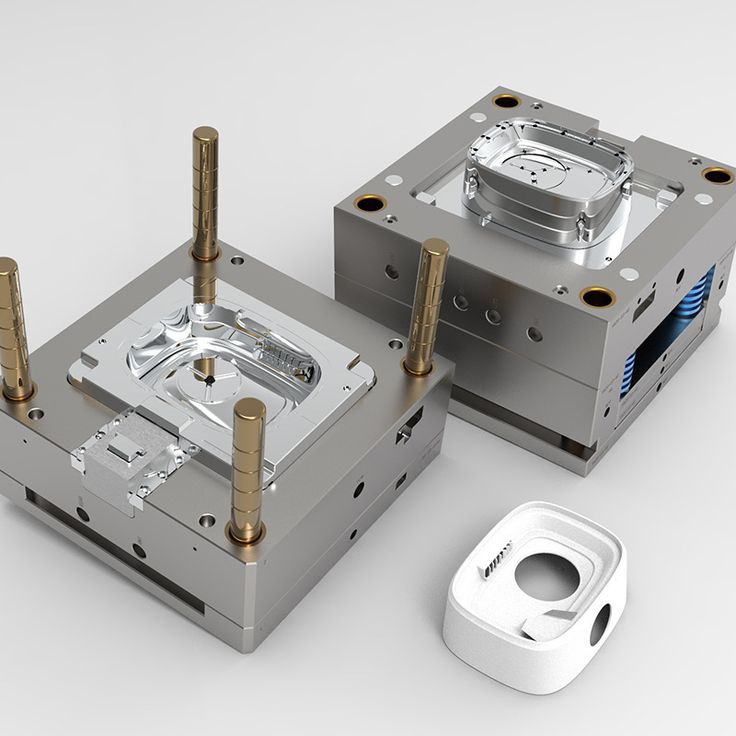

Mold manufacturing is the critical first step in the injection molding process. It involves designing and building the high-precision metal molds that shape your plastic parts. Our company combines expert mold designers with state-of-the-art machining to create molds that guarantee accurate, consistent parts. We use advanced CAD/CAM software and conduct mold flow analyses to optimize each mold design for longevity and performance.

Our Mold Making Capabilities

-

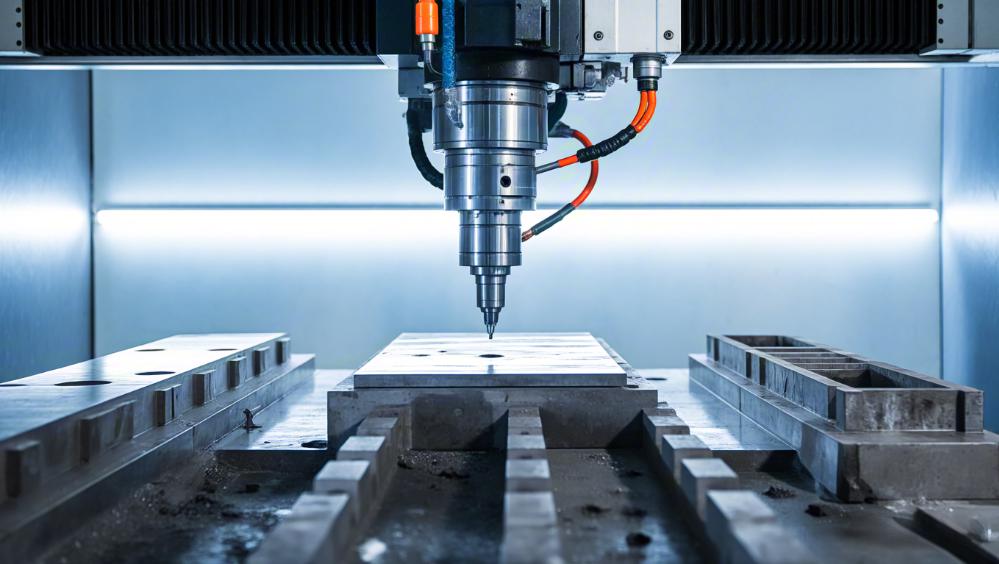

Advanced Machinery & Precision

Equipped with high-speed CNC mills, EDM (electrical discharge machining), and wire-cut machines, we fabricate mold components to tolerances within microns. This ensures each cavity and core is perfectly shaped for your product.

-

Experienced Tooling Team

Our mold engineers have 20+ years of experience in mold design and fabrication. They can handle complex mold structures (e.g. multi-cavity, overmolding inserts) and ensure optimal cooling and ejection systems for efficient production.

-

Quality Materials & Standards

We construct molds using hardened tool steels (such as P20, H13) and standard components (DME/HASCO), ensuring durability for high-volume production. Each mold undergoes rigorous testing and polishing to achieve the required surface finish and part quality.

-

Capacity & Efficiency

With an in-house tooling workshop operating 24/7, we can produce dozens of molds per month. Our efficient project management and DFM (Design for Manufacturability) approach reduce lead times and cost – delivering production-ready molds in as fast as 2-6 weeks (depending on complexity).

FAQs

Q: What sizes and types of molds can you manufacture?

A:We build molds ranging from small high-precision micro-molds to large automotive-panel molds. Our equipment handles mold bases up to several tons in weight. We make prototype molds, multi-cavity production molds, insert molds, and family molds, tailoring each to client specifications.

Q: How do you ensure mold quality and longevity?

A:Quality is ensured through every step: we use certified steel, perform heat treatment for hardness, and apply precision finishing. Before shipment, each mold is trialed in-house to validate it produces dimensionally accurate parts. We also offer lifetime mold maintenance and repairs to keep your production running smoothly.

Q: Can you assist with mold design and DFM?

A:Yes, our engineering team works closely with you on design for manufacturability. We provide mold design optimizations, mold flow analysis reports, and suggest improvements (e.g. adding draft angles or optimizing gate locations) to ensure the mold will produce high-quality parts efficiently.