Injection Molding Services

– Efficient Production at Scale.

Introduction

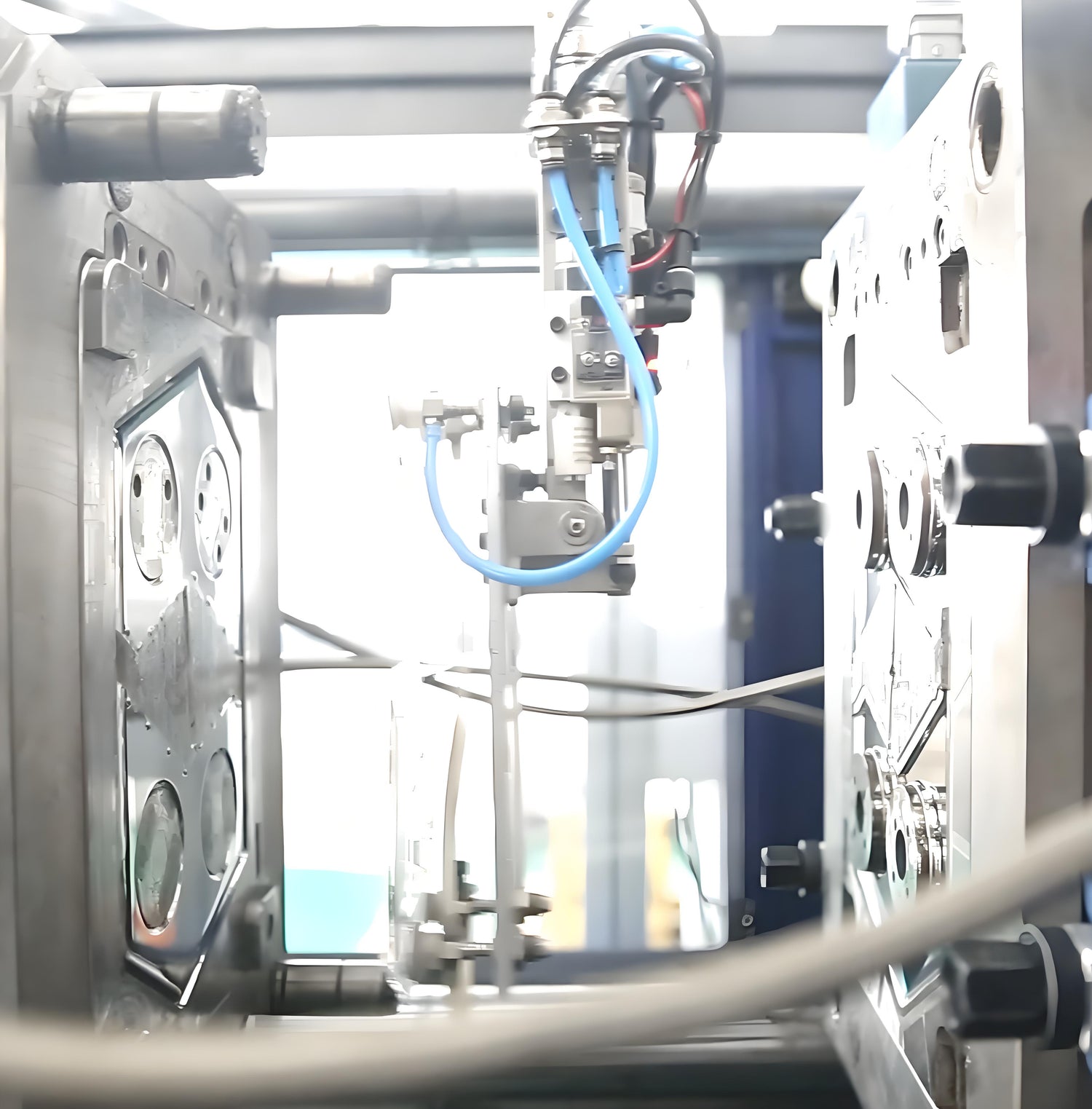

Injection molding is a mass-production process for plastic parts, ideal for achieving low unit costs and consistent quality at high volumes. In this stage, molten plastic is injected into the precision molds to form your product. Our company operates a cutting-edge injection molding facility that can produce everything from small intricate components to large structural parts. We ensure each part meets exact specifications through controlled processing and strict quality checks. Our experience spans various industries – from consumer electronics to automotive – which means we can handle diverse requirements with confidence.

Our Molding Capabilities

-

Modern Machine Fleet

We run over 20 injection molding machines ranging from 80 to 380 tons clamping force. This range gives us the flexibility to mold tiny precision parts as well as sizable components. Our facility is designed for 24/7 operation, with automated part pickers and conveyors to boost efficiency.

-

Wide Material Expertise

We have expertise in molding a broad range of thermoplastics – ABS, PC, PP, Nylon, TPU and more. Each material is processed with the right temperatures and pressures to maintain its properties. We also handle specialty resins (glass-filled, flame-retardant, medical grade) and can provide guidance on material selection for your project.

-

Quality Assurance

Quality is built into our process. We are ISO 9001 certified, and our quality team performs in-process inspections on every production run. We utilize precise cavity pressure control, regular dimensional checks (using calipers, CMM, etc.), and statistical process control to ensure each batch meets your specifications. Defective parts are caught and corrected immediately, guaranteeing consistency and reliability

-

High Volume & Efficiency

Our multi-cavity molds and optimized cycle times enable high-volume output to meet tight deadlines. We employ scientific molding principles to minimize waste and cycle time, achieving efficient production with low scrap rates. For suitable projects, we also use robotic arm automation for part removal and packaging, reducing labor and speeding up throughput.

FAQs

Q: What is your production capacity?

A:We can handle both small prototype runs and large-scale production. For example, a single production mold can output thousands of parts per day. We manage scheduling across multiple machines to fulfill orders of millions of parts per year. If you have specific volume targets, we will allocate the needed machinery and shifts (we operate 3 shifts if required) to meet your demand.

Q: How do you maintain consistency across large orders?

A:Consistency is achieved through rigorous process control. We document and program optimal parameters for each part (temperature, injection speed, cooling time, etc.). Our machines are regularly calibrated, and we use automated material feeding and drying systems to ensure material stability. Additionally, our quality team performs first-article inspections and periodic sample checks during the run. We providequality reportsupon request, so you have full transparency.

Q: Can you mold overmolded or insert-molded parts?

A:Yes, our capabilities include overmolding(molding one material over another, such as a soft TPE grip on a hard plastic part) and insert molding(encapsulating metal inserts or threaded bushings within plastic). We have specialized equipment and know-how for these processes, ensuring strong bonds between materials and precise alignment of inserts.